为什么我的TP钱包没有转账记录?

什么是钱包? 钱包是一款由天翼推出的数字货币钱包,主要支持比特币、莱特币、以太坊等主流数字货币。用户可以通过钱包进行数字货币存储、转账、交易等...

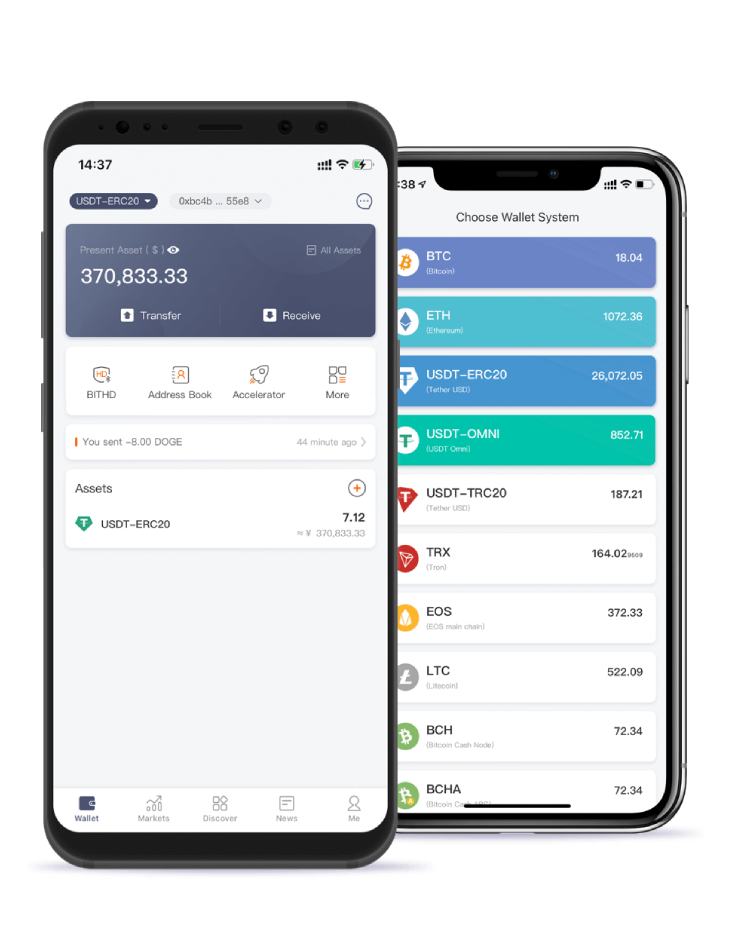

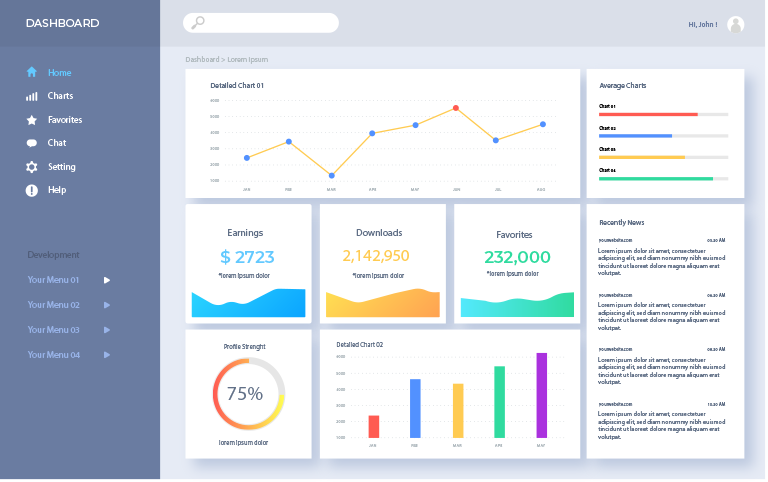

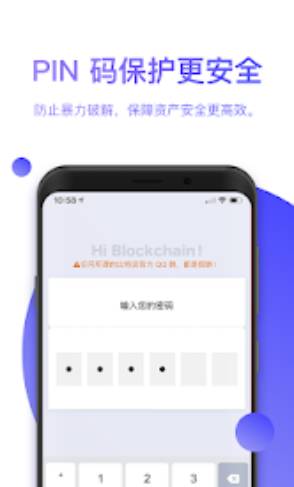

TP钱包官网下载_Tokenpocket官方app最新版是全球领先的去中心化多链钱包,支持 BTC/ETH/TRX/USDT 等多种区块链资产。TP钱包官网下载_Tokenpocket官方app最新版致力于为全球用户提供安全的资产管理以及丰富的区块链应用服务,使用TP钱包官网下载_Tokenpocket官方app最新版,用户可以在方便的使用应用服务的同时确保资产 100% 由自己掌控

发现更多

基于比太技术,多层防护,至今已为用户保管千亿级资产,从未发生过一起技术安全事故。

逻辑简单易懂,极致丝滑体验,处处尽显慧心巧思。

理想现实的美妙结合,对接多方服务,丰富应用场景。

我们开源的钱包代码、Kafka_Plugin及MiniWallet SDK、Mobile SDK等都在这里.

TP钱包官网下载_Tokenpocket官方app最新版被列为EOSIO Labs通用授权库之一.

TP钱包官网下载_Tokenpocket官方app最新版是全球领先的多链钱包,支持BTC/ETH/TRX/USDT 等多种区块链资产。使用TP钱包官网下载_Tokenpocket官方app最新版,用户可以在方便的使用应用服务的同时确保资产100% 由自己掌控。

迄今为止最好的多链钱包,具有很多功能,虽然在极少数情况下它会在通过 Dapp 浏览器连接到某些网站时崩溃,但这不是问题,喜欢这个钱包。

这很容易成为以太坊的最佳移动钱包。 我已经尝试了所有主要选项,这个钱包具有最好的可靠性和最好的用户界面。 TP钱包官网下载_Tokenpocket官方app最新版 树立了行业标准。 当我不在电脑前并且想与区块链交互时,我会打开 TP钱包官网下载_Tokenpocket官方app最新版。

这是一个有趣的应用程序。 如果每个人都想获得一个数字钱包,我会推荐给他们,这是一个去中心化的应用程序(钱包)并且在区块链系统上系统地工作。 他们想从事网络营销、自由职业等在线业务。 这是一个安全的应用程序。 (致创作者)我们感谢您精美的应用程序,我们希望您将来提供更多应用程序。 在这里谢谢 kamran hashmi,和平✌️.

我喜欢这个应用程序的用户体验。 只需轻点几下,我就创建了我的钱包。 使用 TP钱包官网下载_Tokenpocket官方app最新版 钱包应用程序发送和接收以太币非常容易。 应用程序运行速度快,用户界面简洁。

这似乎非常安全,只要确保你不把这个短语告诉任何人。 把它放在安全的地方。 从 Apple 和 Google Play 商店下载和安装都非常容易。 就是这样。 按照说明进行操作。

我喜欢这个应用程序,但我认为在我真正让我的合作伙伴使用该应用程序之前,应该解决和修复一些主要故障。

我从不写评论,但认为这是值得的,已经使用加密货币几个月,并且总是难以购买加密货币并快速获得它这是一个很大的帮助购买了 .5 eth 并且能够在 5 分钟内使用它

TP钱包官网下载_Tokenpocket官方app最新版是全球领先的多链钱包,支持BTC/ETH/TRX/USDT 等多种区块链资产。使用TP钱包官网下载_Tokenpocket官方app最新版,用户可以在方便的使用应用服务的同时确保资产100% 由自己掌控。

什么是钱包? 钱包是一款由天翼推出的数字货币钱包,主要支持比特币、莱特币、以太坊等主流数字货币。用户可以通过钱包进行数字货币存储、转账、交易等...

为什么钱包没有交易所? 钱包是一个支持多种数字资产的钱包应用程序。像比特币、以太坊、和这样的数字货币都可以在上面进行存储和管理。然而,钱包缺少交易...